Services

At Claromech we are aware that everyone has different needs and resources so we provide a flexible approach where we are happy to provide whichever elements of advice, design, manufacture, programming or training are required.

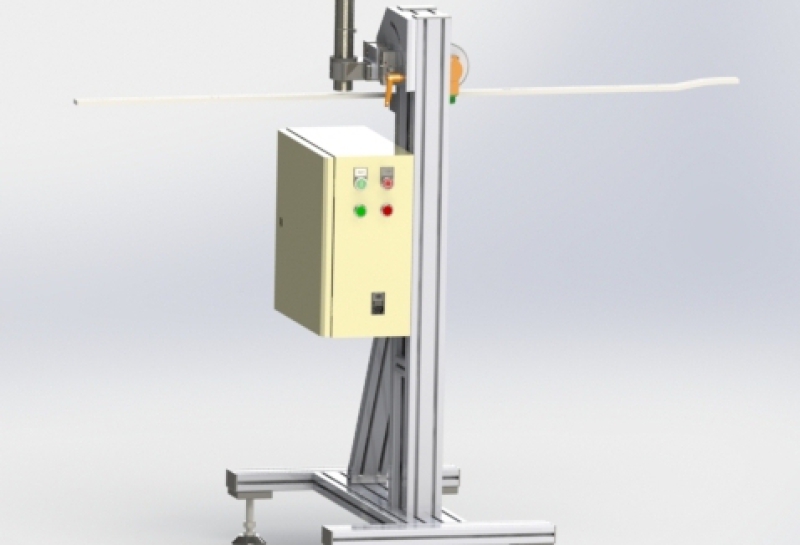

Concept Design / Feasibility Trials

We use Solidworks 3D CAD to provide indicative designs for proposals. We find that creating these early stage designs allows our customers to easily visualise the concept and provides a great platform for discussion, leading to optimisation of critical elements at an early stage.

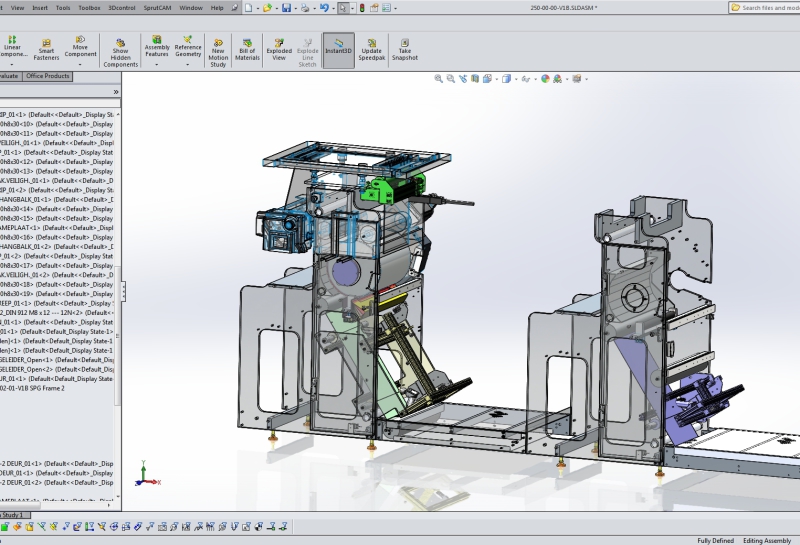

Detailed Mechanical Design

We use the latest versions of Solidworks 3D CAD to allow us to accurately model our equipment designs. This allows us to confirm that all components will fit correctly before cutting metal, and also provides customers with the opportunity to carry out final design reviews.

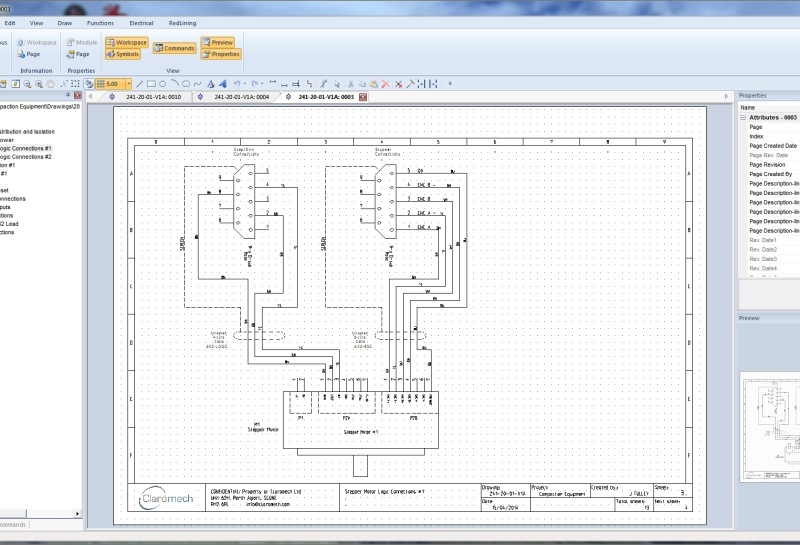

Control Design

We have experience in a wide range of control equipment, from PLC's and motion controllers, stepper and servo motors, temperature control, inkjet coding and of course machine safety. Our electrical and pneumatic designs are fully documented and we also provide documented copies of any software written for our bespoke equipment.

Manufacture

We have the in-house capabilty to carry out a number of manufacturing tasks such as manual turning and 3D printing, however we also have good relationships with a wide variety of sub-contractors providing us with additional manufacturing capacity in areas such as CNC machining, sheet metal fabrication, laser cutting, water jet cutting and PCB manufacture.